Accredited Testing Laboratory

Elektrizace železnic Praha a. s. accredited testing laboratory for mechanic tests serves for testing of own products and components for overhead contact line but also other subjects are invited for testing, e.g. for analyses and experts‘ reports during the process of determination of the causes of failures and damages of parts of contact lines in operation on railway and public transport.

Indoor Testing Laboratory

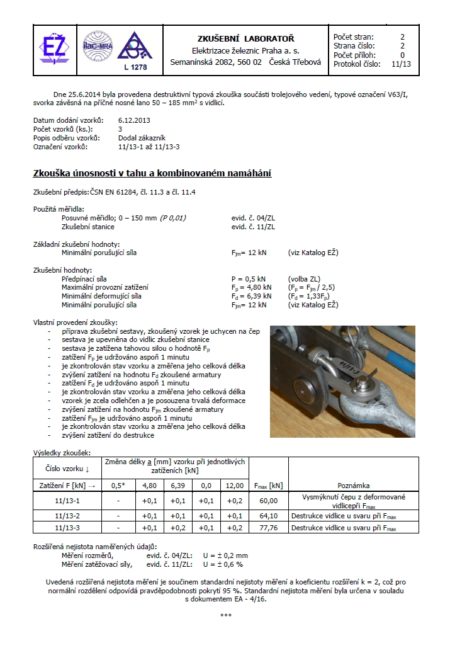

Elektrizace železnic Praha a.s. testing laboratory has been accredited by the Czech Certification Institute (since 2000 acc. to ČSN EN ISO/IEC 17025). Its scope includes performing tension (pressure) tests of armatures and elements of overhead contact line for railway, trams and trolleybuses and outdoor lines in the following range: checking of dimensions, measuring of the thickness of dip Zn coating by a magnetic method, checking of armatures bolt connections, strength of conductor mounting, tension carrying capacity tests, combined stress tests and mechanical strength test of construction elements. Maximum tension (pressure) is 100 kN with the measuring accuracy of ± 1 %, max. length of a tested object is 3 200 mm, preselected or individual tests in a force or position bonding.

The output from the performed test is an accredited protocol. Acc. to the customer’s requirement it is possible to provide the protocol with a graphic test record, photodocumentation or videodocumentation.

Outdoor Testing Laboratory

Tests of larger objects are performed here. Loading is realized by the means of a mobile hydraulic aggregate and portable tensiometers. Loading is limited to 50 kN.

The testing laboratory is equipped as follows:

- Hardness tester / Wolpert Wilson Instruments / Testor MRD 600, 20-100 HRC

- Linear height gauge LH – 600D + granite table

- Roughness tester SJ – 201P

Contact persons

Jiří Přibyl – Jiri.Pribyl@elzel.cz |